Have you ever encountered a puzzling error code flashing on your Toyota forklift’s display? You’re not alone! These codes, often cryptic and confusing, can be a real headache for operators and technicians alike. One common code, “E A5-1,” can send chills down the spine, as it often indicates a crucial component malfunction. But fear not, understanding this error and its potential causes can empower you to troubleshoot and resolve the issue with confidence.

Image: smartadm.ru

This article delves into the world of Toyota forklift diagnostics, specifically focusing on the E A5-1 code. We will explore its meaning, potential causes, and practical steps you can take to diagnose and rectify the problem. Whether you are a seasoned forklift operator, a technician seeking to expand your knowledge, or simply curious about the inner workings of these powerful machines, this guide will equip you with the necessary information to navigate this common yet critical code.

Understanding the E A5-1 Code: A Gateway to Troubleshooting

The E A5-1 code is a diagnostic message that appears on the display of Toyota forklifts, signaling a potential malfunction with the vehicle speed control system. The code itself doesn’t reveal the specific cause, rather it acts as a starting point for the troubleshooting process. To delve deeper, you need to understand the components that contribute to the forklift’s speed control, including:

- Throttle Sensor: This sensor measures the position of the throttle and sends this data to the control unit, informing the system about the desired speed.

- Speed Sensor: This sensor monitors the actual speed of the forklift and transmits the data to the control unit for comparison with the desired speed set by the operator.

- Control Unit: This sophisticated “brain” receives the data from the throttle and speed sensors, processes the information, and sends commands to the hydraulic system to regulate the forklift’s speed.

- Hydraulic System: This complex network of components delivers hydraulic pressure to the various actuators that drive the forklift.

When the E A5-1 code appears, it means the control unit has detected an inconsistency within the speed control system. This might be a mismatch between the desired speed and actual speed, a faulty sensor reading, or a communication error between the sensors and the control unit.

Unraveling the Mystery: Potential Causes of E A5-1

Now that we understand the basic mechanics of the speed control system, let’s explore the most likely culprits behind the E A5-1 code:

1. Throttle Sensor Malfunction

The throttle sensor is responsible for transmitting accurate information about the desired speed. If the sensor is malfunctioning, it could be sending incorrect data to the control unit, leading to a discrepancy between intended speed and the measured speed, triggering the E A5-1 code. This could be caused by:

- Damage or Wear: The sensor might be physically damaged due to vibrations, impacts, or exposure to harsh environments.

- Contamination: Dust, dirt, or debris can accumulate on the sensor, interfering with its operation.

- Electrical Fault: A short circuit, loose connection, or defective wiring in the sensor circuit can also disrupt the sensor’s transmission of data.

Image: www.forkliftrivews.com

2. Speed Sensor Malfunction

The speed sensor is equally crucial in regulating the forklift’s speed. If this sensor malfunction, the control unit receives inaccurate information about the actual speed, ultimately causing the E A5-1 code to appear. Common causes include:

- Damage or Wear: Similar to the throttle sensor, the speed sensor could also be damaged due to mechanical wear and tear or environmental factors.

- Misalignment: The speed sensor might be misaligned, leading to inaccurate readings.

- Electrical Fault: Similar to the throttle sensor, a short circuit, loose connection, or wiring issue in the sensor circuit can disrupt its functionality.

3. Control Unit Malfunction

The control unit, the central processing unit of the forklift’s electrical system, is responsible for interpreting the data from the sensors, making calculations, and sending commands to the hydraulic system. If the control unit malfunctions due to defective components or software errors, it can generate the E A5-1 code.

4. Hydraulic System Issues

While less common, problems with the hydraulic system, such as leaks, blockages, or malfunctioning components, can create inconsistencies in the forklift’s operation, ultimately triggering the E A5-1 code.

Troubleshooting Strategies: A Step-by-Step Approach

To effectively troubleshoot the E A5-1 code, you need to methodically eliminate potential causes. Here’s a step-by-step approach:

1. Visual Inspection: Look for Obvious Clues

Start by thoroughly inspecting the throttle and speed sensors for any visible damage, wear, or contamination. Check for any loose connections or damaged wiring. A visual inspection can often identify the root cause without needing to delve deeper. If you notice any issues, address them before moving onto the next steps.

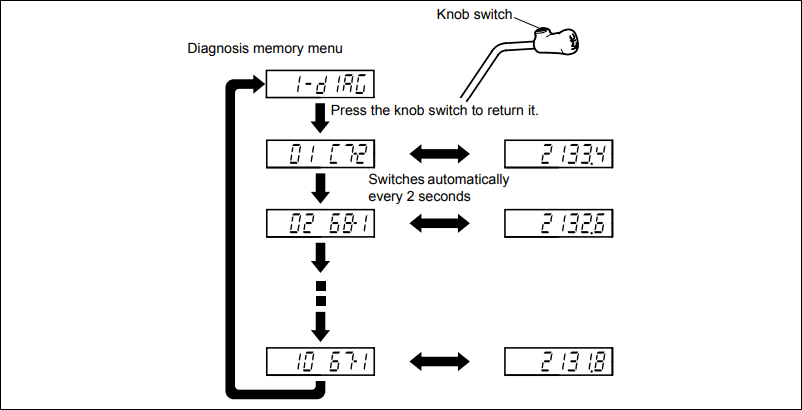

2. Use a Diagnostic Tool

Toyota forklifts come equipped with diagnostic tools that offer a wealth of information about the forklift’s status. Use this tool to read both the E A5-1 code and any other error codes that might provide further clues about the problem. The tool can also display real-time data from the throttle and speed sensors, allowing you to verify their readings.

3. Check for Electrical Faults

Once you’ve eliminated visible causes, it’s essential to investigate any electrical faults that could be contributing to the E A5-1 code. Use a multimeter to test the electrical circuits for continuity, voltage, and resistance. Pay particular attention to the wiring and connectors of the throttle and speed sensors, as well as the control unit. If you detect any electrical issues (e.g., short circuits, broken wires, loose connections), address them before proceeding.

4. Consider the Control Unit

If the visual inspection, diagnostic tool readings, and electrical tests haven’t revealed the culprit, consider the control unit. While control unit failures are less frequent, it’s important to consider this possibility. If the control unit is faulty, it might need replacement. Consult with a Toyota dealership or a qualified forklift technician for an appropriate course of action.

5. Investigate the Hydraulic System

As a last resort, if other troubleshooting steps haven’t yielded any results, consider checking the hydraulic system. Look for leaks, blockages, and ensure all hydraulic components are functioning as intended.

Beyond the Code: Preventative Maintenance

Preventing the E A5-1 code from appearing in the first place is paramount. Here are some preventative maintenance practices you can adopt:

- Regular Inspections: Periodically inspect the throttle and speed sensors for any signs of damage, wear, or contamination. Cleanse the sensors with a suitable cleaning agent if necessary.

- Electrical Checks: Regularly check the wiring and connectors for any loose connections, corrosion, or damage.

- Hydraulic Maintenance: Consistently monitor the hydraulic fluid levels, check for leaks, and replace the fluid as recommended by the manufacturer.

- Proper Operation: Avoid subjecting the forklift to excessive wear and tear, use it within its rated capacity, and adhere to proper operating procedures.

E A5-1 Code On Toyota Forklift

Conclusion: Empowering Yourself with Knowledge

The E A5-1 code on a Toyota forklift can be a confusing and daunting experience. However, by understanding the potential causes, implementing effective troubleshooting strategies, and adopting preventive measures, you can effectively diagnose and resolve the issue. Armed with the knowledge from this article, you can confidently approach this diagnostic code and ensure your Toyota forklift continues to operate reliably and efficiently.

Remember to always consult with a qualified forklift technician or Toyota dealership for assistance when troubleshooting complex issues or performing repairs. Stay informed, be proactive, and maintain your forklift properly to avoid encountering the E A5-1 code in the future!