Imagine running a bustling cafe. You’re constantly juggling orders, ensuring ingredients are readily available, and minimizing waste. But what if there was a mathematical formula to help you decide exactly how much coffee beans to order each time, striking the perfect balance between meeting demand and avoiding unnecessary storage costs? This, my friends, is the magic of the Economic Order Quantity (EOQ) model, and it’s a game-changer for businesses across industries.

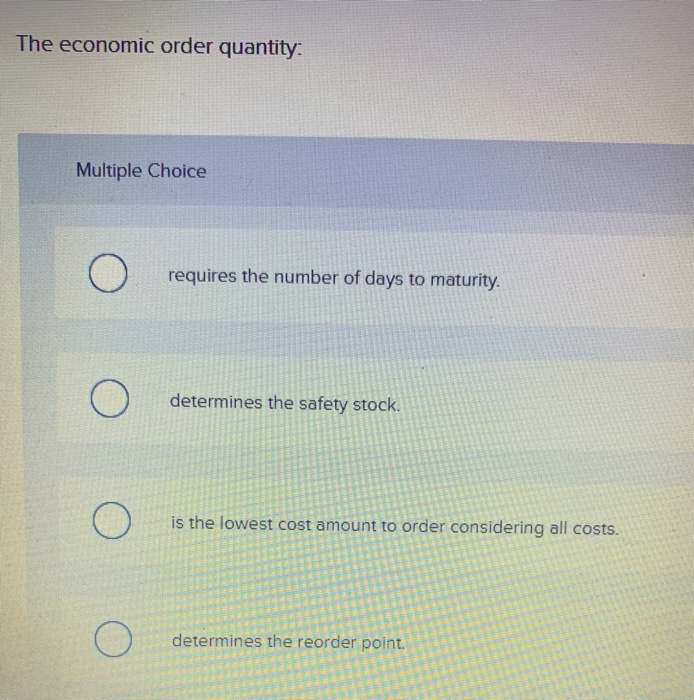

Image: www.chegg.com

But let’s be real, understanding the intricacies of EOQ can feel like navigating a maze of formulas and calculations. That’s why today, we’ll delve into the world of EOQ, exploring its practical applications and unraveling the secrets of its implementation through real-world example problems. Armed with this knowledge, you’ll be able to optimize your inventory management, minimizing costs and maximizing efficiency.

Understanding the Economic Order Quantity Model

What is EOQ?

The Economic Order Quantity (EOQ) is a mathematical formula used to determine the optimal order quantity for inventory. In simpler terms, it tells you the ideal amount of a particular item to purchase at a time, balancing the costs of ordering too much (holding costs) and ordering too little (ordering costs). Imagine trying to find that “sweet spot” in your coffee bean orders, ensuring you have enough to keep your cafe buzzing without hoarding a mountain of beans that might expire!

The Importance of EOQ

In the dynamic world of business, balancing costs and maximizing efficiency is paramount. The EOQ model helps businesses make informed decisions about their inventory, leading to several benefits:

- Reduced Ordering Costs: By placing fewer, larger orders, businesses can minimize the cost of processing each individual order, such as administrative overhead and shipping fees.

- Lower Holding Costs: Holding excessive inventory is expensive. The EOQ model helps optimize inventory levels, minimizing storage costs, spoilage, and obsolescence.

- Minimizes Stockouts: By calculating the ideal order quantity, EOQ reduces the risk of running out of essential goods, ensuring smooth operations and avoiding lost sales opportunities.

- Improved Cash Flow: Efficient inventory management through EOQ allows businesses to utilize their cash flow effectively, allocating funds strategically for other important aspects.

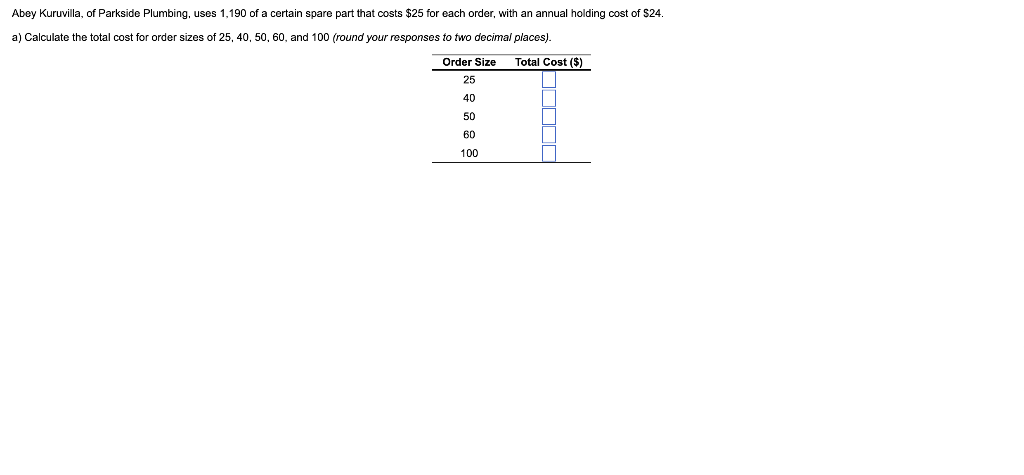

Image: www.chegg.com

The EOQ Formula

The magic behind EOQ lies in its formula, which looks a bit intimidating at first glance, but is actually quite straightforward to understand:

EOQ = √(2DS / H)

Where:

- D = Annual Demand (number of units demanded per year)

- S = Ordering Cost (cost of placing one order)

- H = Holding Cost (cost of holding one unit of inventory for one year)

Let’s break down these elements using our cafe example. Imagine you need 10,000 pounds of coffee beans per year (D = 10,000). Each order costs $50 (S = 50), and holding one pound of coffee beans for a year costs $2 (H = 2). Plugging these values into the formula, we get:

EOQ = √(2 * 10,000 * 50 / 2) = √500,000 = 707.11 pounds

This means you should order approximately 707 pounds of coffee beans each time to minimize your overall inventory costs.

EOQ Example Problems with Solutions PDF

Now, let’s dive into some real-world examples to solidify our understanding of EOQ:

Example Problem 1: The Bookworm Bookstore

A bookstore sells 10,000 copies of a popular novel each year. The cost of placing an order is $25, and the cost of holding one copy of the novel for a year is $5. What is the bookstore’s EOQ?

Solution:

- D = 10,000 (annual demand)

- S = $25 (ordering cost)

- H = $5 (holding cost)

EOQ = √(2 * 10,000 * 25 / 5) = √100,000 = 316.23 copies

The bookstore should order approximately 316 copies of the novel each time to optimize inventory management.

Example Problem 2: The Tech Gadget Emporium

A tech retailer sells 5,000 smartphones annually. The cost of placing an order is $100, and the cost of holding one smartphone for a year is $20. Calculate the EOQ.

Solution:

- D = 5,000 (annual demand)

- S = $100 (ordering cost)

- H = $20 (holding cost)

EOQ = √(2 * 5,000 * 100 / 20) = √50,000 = 223.61 smartphones

The tech retailer should order approximately 224 smartphones each time to minimize inventory costs.

Example Problem 3: The Bakery Delight

A bakery makes 1,000 loaves of bread per week. The cost of placing an order for flour is $30, and the cost of holding one bag of flour for a week is $1. What is the EOQ for flour?

Solution:

- D = 1,000 (weekly demand)

- S = $30 (ordering cost)

- H = $1 (holding cost)

EOQ = √(2 * 1,000 * 30 / 1) = √60,000 = 244.95 bags of flour

The bakery should order approximately 245 bags of flour each time to optimize flour inventory management.

PDF Resources for EOQ Example Problems

Want to delve deeper into EOQ and explore more complex examples with comprehensive solutions? The internet offers a treasure trove of resources, including:

- Academic Journals: Explore publications like “Production and Operations Management,” “Journal of Operations Management,” and “International Journal of Production Economics” for extensive analysis and real-world case studies.

- University Course Materials: Many universities make their course materials available online, providing lectures, exercises, and solutions for EOQ and related inventory management topics.

- Online Educational Platforms: Websites like Coursera, Udemy, and edX offer courses and tutorials dedicated to inventory management, including detailed explanations of EOQ.

- Industry-Specific Resources: Search for resources within your industry to find practical EOQ applications and case studies tailored to your specific needs.

Expert Tips for Effective EOQ Implementation

While the EOQ formula is a powerful tool, it’s essential to remember that it’s a simplified model. To maximize its effectiveness, consider these insights:

- Accuracy is Key: Ensure you have accurate data for your annual demand (D), ordering cost (S), and holding cost (H). Inaccurate data will lead to inaccurate EOQ calculations.

- Seasonality: If your product demand fluctuates throughout the year (e.g., peak holiday season), adjust your EOQ accordingly. You might need to order more during high-demand periods and less during slow seasons.

- Lead Time: Factor in the lead time for your orders – the time it takes from placing an order to receiving the goods. This will help you calculate your reorder point, ensuring you have enough inventory to cover the lead time before you run out.

- Inventory Management Software: Utilize inventory management software to automate EOQ calculations, track inventory levels, and trigger automated reorders when necessary.

FAQs about Economic Order Quantity

Let’s address some common questions about EOQ:

- Q: Is EOQ suitable for all businesses?

A: While EOQ is a valuable tool, it might not be suitable for every situation. Businesses with limited storage space, highly perishable goods, or unpredictable demand might need to explore alternative inventory management strategies.

- Q: How often should I recalculate my EOQ?

A: Recalculate your EOQ regularly, ideally at least once per quarter, to account for changes in demand, costs, and other factors that might affect your inventory needs.

- Q: What are some real-world examples of industries where EOQ is used?

A: EOQ is used across various industries, including manufacturing, retail, healthcare, technology, and hospitality, helping optimize inventory management for products ranging from manufacturing components to books in a bookstore.

Economic Order Quantity Example Problems With Solutions Pdf

Conclusion

Mastering the EOQ model is a crucial step towards optimizing your inventory management, minimizing costs, and maximizing efficiency. By understanding the EOQ formula, applying it to real-world scenarios, and leveraging expert advice, you can make informed decisions about your inventory, ensuring that you have just the right amount of goods on hand at the right time.

Are you ready to unlock the power of EOQ in your business? Let us know in the comments below!