Have you ever tried to bend a piece of metal and wondered how many times you’d need to hit it to get the perfect curve? Or perhaps you’re working on a project that requires precise bends and you want to know how many shots it takes to achieve the desired results. The answer isn’t always straightforward. The number of shots required to produce a specific bend depends on several factors, including the metal’s thickness, material, and desired bend angle, as well as the tools and techniques used. In this comprehensive guide, we’ll delve into the intricacies of determining the number of shots needed for a specific bend, providing you with the knowledge to achieve your bending goals with precision.

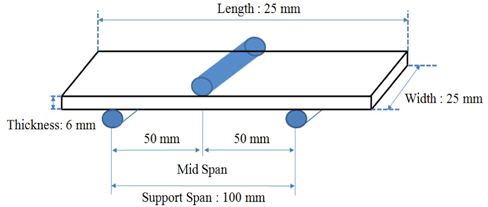

Image: oak.go.kr

I remember the first time I attempted to bend a piece of metal. I was excited to try my hand at metalworking, but I quickly realized that I had no idea how many times I needed to strike the metal to get the desired curve. I ended up overdoing it, creating a much more significant bend than I intended. It was a humbling experience, but it taught me the importance of understanding the relationship between the number of shots and the resulting bend.

Understanding the Factors Influencing the Number of Shots

The number of shots required to produce a specific bend is not a fixed value. It’s influenced by several variables that must be considered for accurate bending.

1. Metal Thickness and Material

The thickness and material of the metal play a critical role in determining the number of shots needed. Thicker metal requires more force and therefore more shots to achieve a bend compared to thinner metal. Similarly, different metals have varying levels of hardness and ductility. For instance, soft metals like aluminum require fewer shots than harder metals like steel.

2. Desired Bend Angle

The desired bend angle is another crucial factor. A smaller bend angle requires fewer shots than a larger bend angle. It’s important to note that the number of shots can vary depending on the specific bending technique used. For example, a gradual bending process using a hammer and anvil might require more shots than a single-shot bending with a specialized press brake.

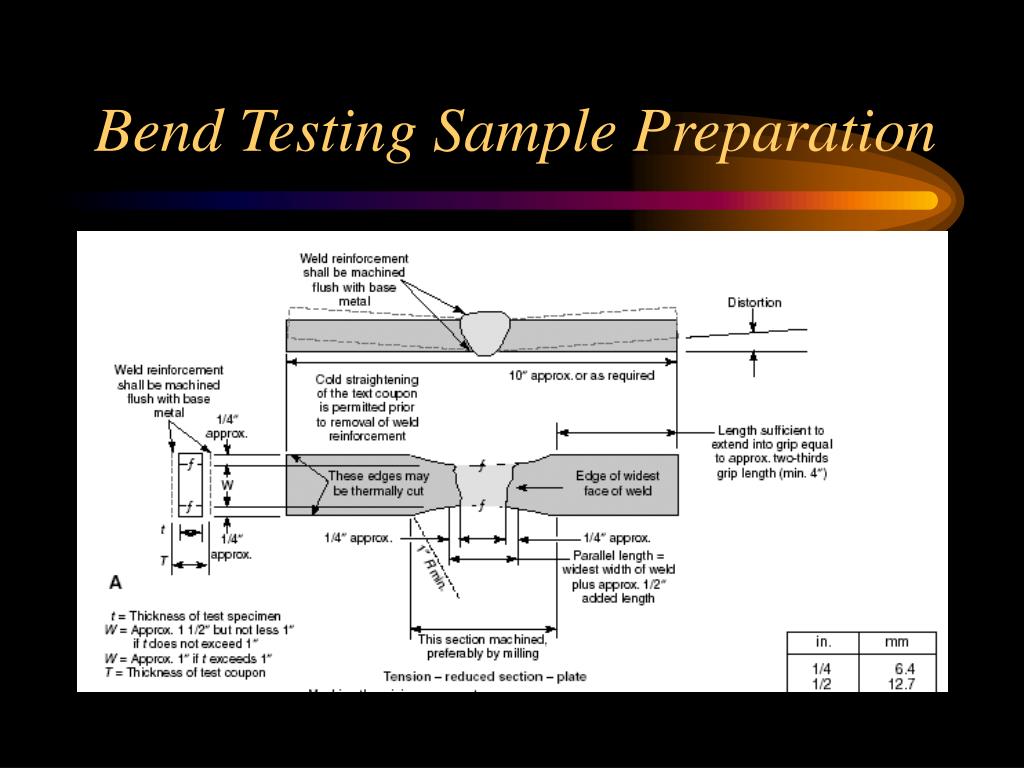

Image: www.slideserve.com

3. Tools and Techniques

The tools and techniques used for bending also impact the number of shots. Different tools, such as hammers, bending brakes, and rollers, have varying levels of force and leverage. The chosen bending technique (e.g., hammering, rolling, or pressing) can significantly affect the number of shots required to achieve the desired bend.

4. Other Factors

Beyond the core factors, other factors can influence the number of shots needed. These include:

- Temperature: Metal can become more malleable at higher temperatures, potentially reducing the number of shots required.

- Work hardening: Repeated bending can cause the metal to work harden, increasing its resistance to bending and potentially requiring more shots to achieve the desired result. A process called annealing can be used to soften hardened metal, making it more pliable.

- Operator skill: A skilled operator can achieve a desired bend with fewer shots than an inexperienced operator.

Determining the Number of Shots – The Practical Approach

While there’s no magic formula to determine the exact number of shots needed, you can employ a practical approach to achieve a specific bend. This approach involves:

- Start with a test bend: On a small test piece of the same metal, perform a few bending trials. This will help you understand how the metal behaves under the chosen bending process and tools.

- Observe and adjust: Monitor the bend angle after each shot, observing the changes and making adjustments as needed. You might need to increase or decrease the force applied, adjust the bend angle, or use different tools for a specific bend.

- Document your results: Keep track of the number of shots required to achieve different bend angles on your test piece. This will help you estimate the number of shots needed for your actual project.

- Start slow and steady: When working on your actual project, start with a small number of shots and gradually increase them as needed. This approach allows for flexibility and prevents overbending.

Tips and Expert Advice for Achieving Optimal Bending Results

To maximize your bending success and minimize the number of shots needed, here are some practical tips:

- Use the right tools: Selecting proper tools for a given job is essential. Hammers, bending brakes, and pressing equipment are designed for specific bending tasks. Utilizing the appropriate tool for your application will lead to more precise bending and reduce the number of shots required.

- Use a jig or fixture: Jigs and fixtures can provide consistent bend angles and reduce the number of shots needed. These tools are particularly useful for repetitive bending tasks.

- Avoid overbending: Overbending can lead to unwanted stress points and damage the metal. Instead of applying excessive force with a large number of shots, focus on achieving the desired bend angle gradually.

- Practice and experiment: The more you practice, the better you’ll become at understanding the relationship between shots and bends. Experiment with different techniques and tools to find the most efficient approach for your projects.

- Don’t be afraid to ask for help: If you’re struggling, seek advice from experienced metalworkers or experienced manufacturing professionals. They can provide valuable insights and guidance.

Practice and careful observation are key to mastering bending techniques. By understanding the factors that affect the number of shots needed, you can enhance the consistency and accuracy of your bending, ensuring that your project meets your expectations.

FAQs about the Number of Shots Needed for a Specific Bend

Here are some frequently asked questions about determining the number of shots needed to produce a specific bend.

Q: What is the optimal number of shots for bending metal?

A: There is no single optimal number of shots. The optimal number depends on the specific factors we’ve discussed, including metal thickness, material, desired bend angle, and the chosen techniques.

Q: Why can’t I find a chart showing the number of shots for every bend?

A: The variables involved in bending make it challenging to create a definitive chart. The number of shots required varies greatly depending on these factors.

Q: What happens if I overbend the metal?

A: Overbending can cause stress points and potentially crack the metal. It can also affect the integrity of your project. Excessive bending can also lead to work hardening, making the metal more difficult to bend in the future.

Q: How do I avoid overbending?

A: It’s best to err on the side of caution. Start with fewer shots and gradually increase the number as needed while closely observing the bend angle.

The Number Of Shots Needed To Produce A Specific Bend.

Conclusion

Understanding the number of shots needed to produce a specific bend is crucial for achieving accurate results in metalworking. By considering the factors that influence the number of shots and practicing diligently, you’ll be able to determine how many times to hit the metal to achieve the desired bend. Always remember that patience and observation are key to achieving success.

What other metalworking techniques are you interested in learning about? Let us know in the comments below and we’ll be happy to share our knowledge!