Have you ever stared at your trusty Craftsman 2 ton floor jack, feeling a bit intimidated by its intricate mechanics? It’s a powerful piece of equipment that can lift a car with ease, but sometimes knowing its internal components can feel like a mystery. Don’t worry, you’re not alone! Understanding the parts of your floor jack not only helps in maintenance and repair but also gives you a deeper appreciation for its engineering brilliance.

Image: viewfloor.co

In this comprehensive guide, we’ll embark on a journey to dissect the Craftsman 2 ton floor jack, uncovering its key components and their functions. You’ll gain a clear understanding of each part and its role in the smooth operation of your jack, equipping you with the knowledge needed to perform basic maintenance and trouble-shooting. Ready to delve into the heart of your trusty lifting companion? Let’s get started!

The Foundation: Understanding the Main Components

Imagine the floor jack as a mini hydraulic system, built with precision to lift substantial weight. It operates through the clever interplay of various components that work together in harmony. Let’s explore the main players in this intricate dance:

1. The Base and Handle: Your Starting Point

- Base: The solid metal base, often featuring a wide footprint for optimal stability. This is your anchor, firmly planted on the ground to provide a secure support for the jack’s actions.

- Handle: A vital part, the handle serves both as a lever for lifting and as a crucial component for lowering the jack.

2. The Lifting Mechanism: The Hydraulic Heart

- Pump: This is the power source, converting the manual force you apply to the handle into hydraulic pressure. It’s like a miniature pump, delivering the force that lifts your car.

- Cylinder: A sturdy, hollow tube that accommodates the hydraulic fluid and houses the piston. This is where the real lifting action takes place.

- Piston: This internal component, connected to the lifting arm, moves within the cylinder, driven by the hydraulic pressure. It’s the muscle that does the heavy lifting.

- Lifting Arm: This part connects to the piston, channeling the upward force and rising as the piston moves up the cylinder. It’s crucial for holding the vehicle securely while it’s lifted.

3. The Control System: Ensuring Precision

- Release Valve: This valve allows you to smoothly lower the vehicle. It regulates the flow of hydraulic fluid from the cylinder, permitting controlled descent.

- Safety Valve: A critical feature protecting against over pressurization, this valve prevents hydraulic fluid from reaching dangerous levels, ensuring your safety and the jack’s integrity.

Anatomy of a Craftsman 2 Ton Floor Jack: Breaking it Down Further

Just like a human body has intricate systems, the Craftsman 2 ton floor jack is composed of various interconnected components. Let’s examine them in detail:

1. The Saddle: The Vehicle Connection Point

- Saddle: This is the crucial part where the jack directly engages with your vehicle’s lifting points. Constructed with durable steel, it carries the weight of your car while it’s elevated.

2. The Linkage: Transmitting The Force

- Linkage Rods: Strong metal rods connecting the handle to the pump and the pump to the cylinder. These rods act as conduits, effectively transferring the force you apply to the handle to the hydraulic system, resulting in the upward movement of the lifting arm.

3. The Hydraulic Fluid: The Lifeblood of the System

- Hydraulic Fluid: This oil-based fluid transmits pressure within the jack. It’s vital for ensuring smooth operation and minimizing friction, similar to the role of blood in the human body.

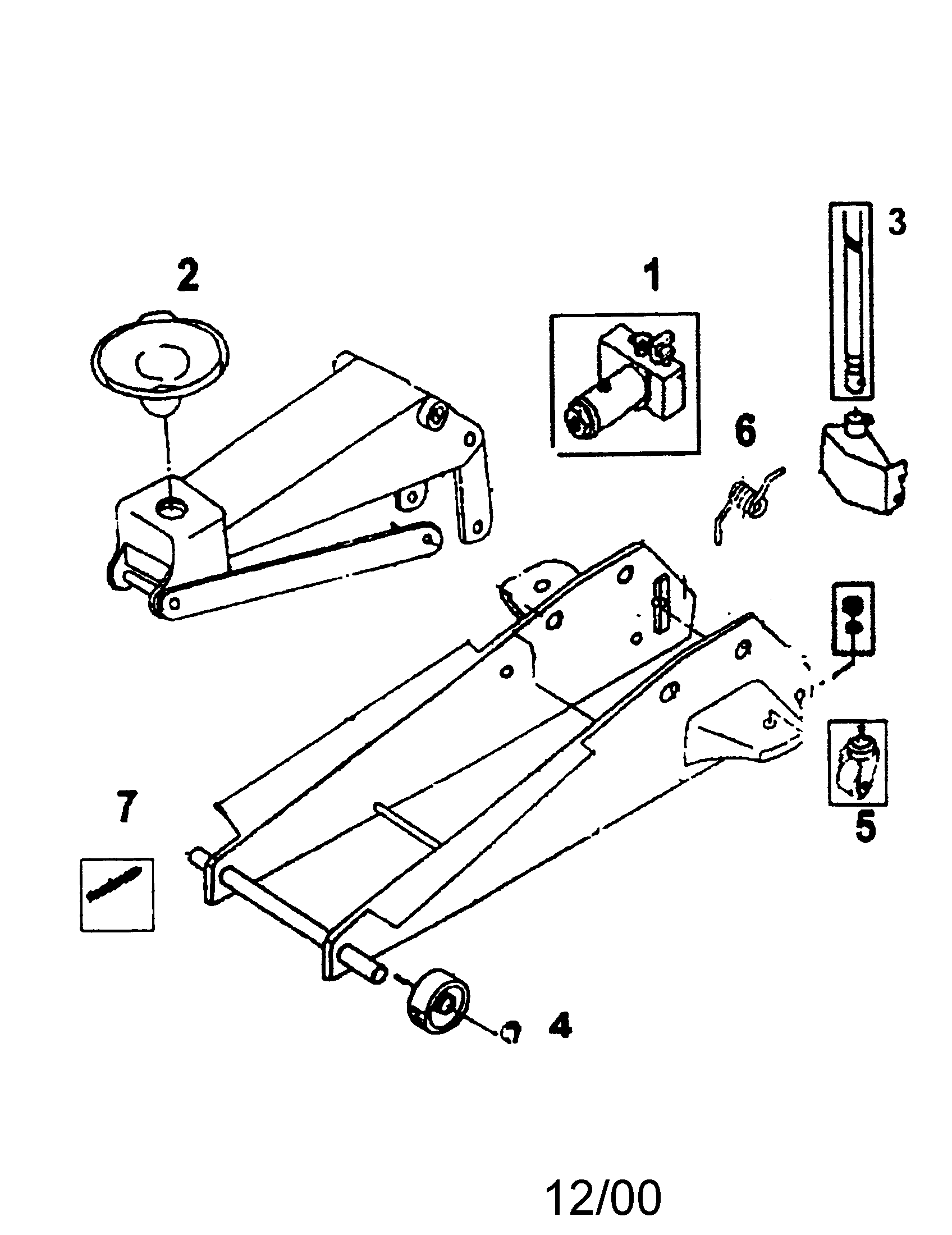

Unlocking the Secrets: A Parts Diagram Decoded

Now that you are familiar with the main components, let’s take a visual journey through a typical Craftsman 2 ton floor jack parts diagram. This visual guide will help you connect the names to the actual parts, giving you a deeper understanding of their roles. (Refer to a visual diagram provided in this section.)

- Base: The foundational structure, providing stability and support.

- Handle: The lever to pump and lower the jack.

- Pump: A vital part that converts mechanical force into hydraulic pressure.

- Cylinder: A hollow tube that houses the piston and the hydraulic fluid, vital for lifting.

- Piston: The component that actually does the lifting, driven by fluid pressure.

- Lifting Arm: Connects to the piston, rising as the piston moves.

- Saddle: The contact point, safely engaging with your vehicle’s jacking points.

- Release Valve: A control valve for smoothly lowering the jack.

- Safety Valve: A safety measure to prevent over pressurization.

- Linkage Rods: Connect the handle to the pump and pump to the cylinder, transmitting force.

Image: wirediagramschwarz.z13.web.core.windows.net

Expert Insights and Maintenance Tips: A Few Valuable Pearls

- Regular Maintenance is Key: Just like any machine, your Craftsman 2 ton floor jack needs regular maintenance to function properly. A critical step is checking the fluid level. Make sure the reservoir is filled with the appropriate hydraulic fluid, ensuring seamless operation.

- Lubrication: Keeping moving parts well lubricated is important. Check the linkage rods and other moving parts for any signs of dryness and lubricate them with the correct type of grease.

- Inspect for Wear: Examine the lifting arm, saddle, and base for any signs of cracks or excessive wear. Replace any worn or damaged parts immediately to ensure safety and optimal performance.

Craftsman 2 Ton Floor Jack Parts Diagram

Conclusion: Mastering Your Craftsman 2 Ton Floor Jack

By now, you’ve journeyed through the intricate mechanics of your Craftsman 2 ton floor jack, understanding its various parts and their functions. You’ve gained the knowledge needed to perform essential maintenance and troubleshoot any minor issues. This empowers you to use your floor jack safely and efficiently, tackling car maintenance tasks with confidence.

Remember, the key to longevity and smooth performance lies in regular maintenance and careful use. Taking care of this powerful piece of equipment will ensure it continues to serve you reliably for many years to come.

Remember, if you encounter any issues beyond your expertise or are unsure about any aspect of your floor jack, consult an experienced mechanic. Their specialized knowledge can provide you with professional advice, ensuring your safety and the longevity of your jack.